Finishing Processes

Fettling – fettling is where the component is passed against an abrasive belt resulting in the grinding of the component. Flash and excess material is fettled and removed by high speed 20 000 rpm pneumatic grinders on robotic manipulators while maintaining critical dimensions.

Clipping – the semi automated rotary trimming presses process components through a cutting die that trims the profile of the components to maintain tight tolerances along the flash/split line.

Vibrocutting & Polishing – vibrocutting and mechanical polishing is achieved when an abrasive medium is added to the vibrating bowl to debur and polish the product.

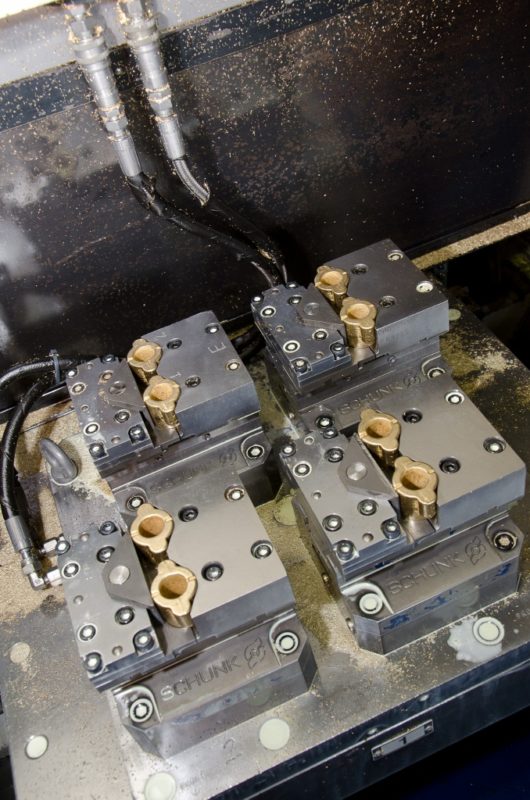

CNC Machining– all machining of components is done on our range of CNC machines with pallet changers and hydraulic clamping fixtures. The CNC machines are standardised for flexibility, maximum uptime and maintenance.

Shot Blasting – components are shot blasted with stainless steel shot to improve the surface finish of the product.